In the spring of 2010 Umeå Institute of Design, and the second year bachelor students, were approached by Swedish packaging company Tetra Pak who wanted to find new and innovative solutions to their packaging.

Minimizing waste and maximizing user satisfaction were the two most important focal points in the project. Since Tetra Pak is one of the largest packaging manufacturers in the world the potential to affect a lot of people on a daily basis is highly possible. Much care therefore needed to be taken to accommodate the users and their individual differences.

Research focused on one side on finding new, emerging, markets where current packaging is either non existent or arcane and on the other on opening up new areas and uses for the packaging. Soup packaging is something which largely uses both old fashioned packaging methods, cans, and where expansion could easily be achieved with the right packaging.

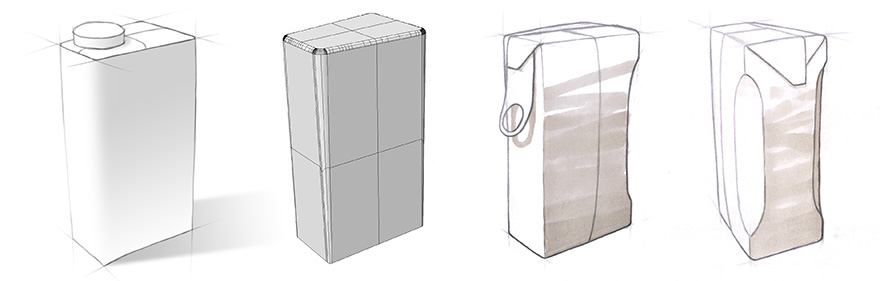

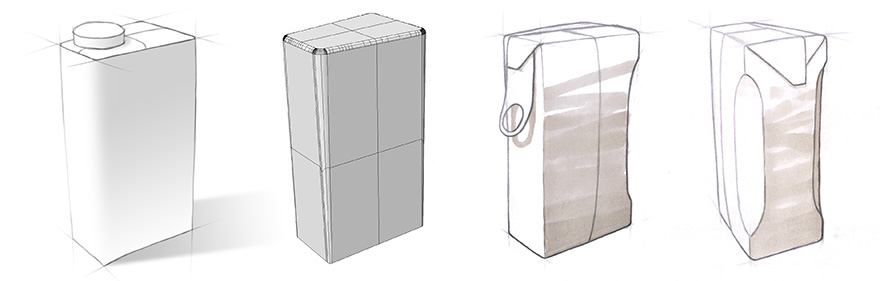

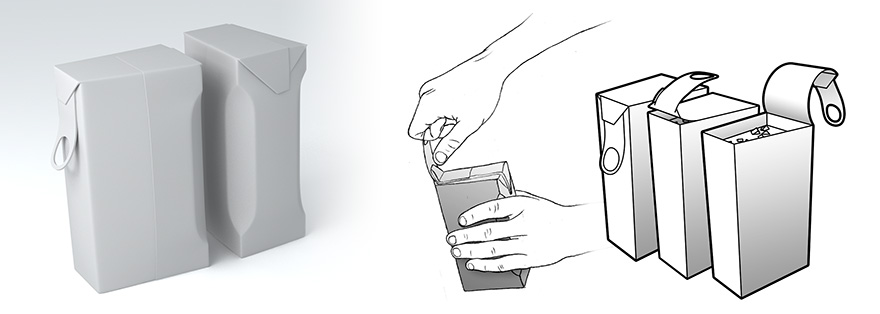

A new package was developed over the course of five weeks. The new package, dubbed Tetra Taper, still retains the qualities of the most basic of Tetra Pak’s current packages, namely to be created completely from one continuous sheet of laminated paper, thus creating no manufacturing waste. Due to the volumes of packaging material manufactured by Tetra Pak on a daily basis even a little waste per package quickly mounts up to vast amounts.

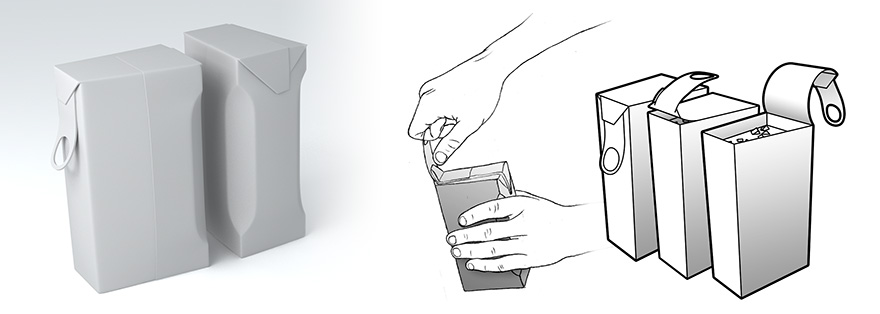

Tetra Taper features a tapered form with chamfered back edges to make handling easier, especially for users with less hand strength. By pulling the large tab the whole top surface of Tetra Taper is removed and the contents accessed. For other applications than soup Tetra Taper could easily be fitted with more conventional tear off tabs or screw caps for resealing.

Due to advances in packaging material Tetra Taper is also safe to microwave, making it possible to both buy, cook and eat your soup from the same package, perfect for lunch boxes. No dirty dishes and while still being completely recyclable a clean conscience to boot.

Tetra Taper is highly customizable with large surfaces for graphic design and colour choices making optimal use of its space in the store. It does this while also minimizing empty air around the packages during shipping due to its interlocking design, helping to save further on shipping costs and CO2 emissions.